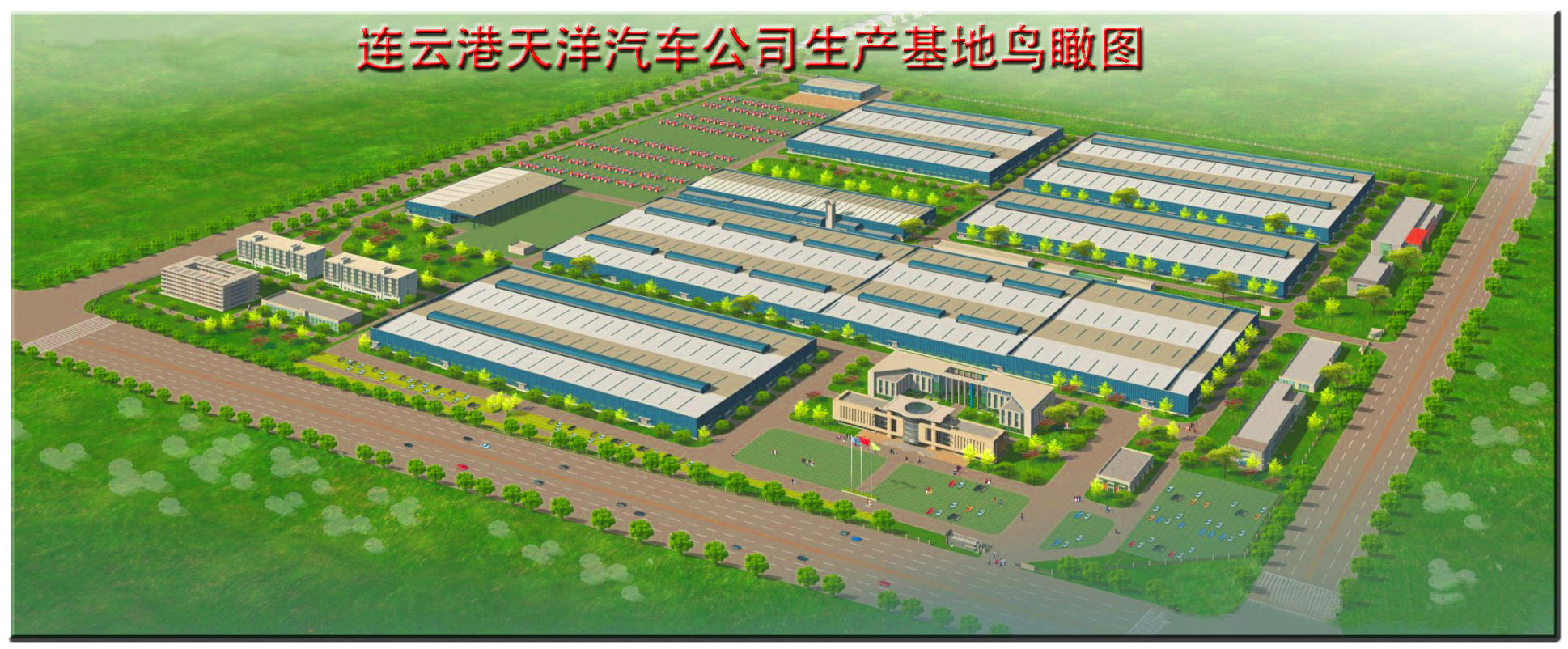

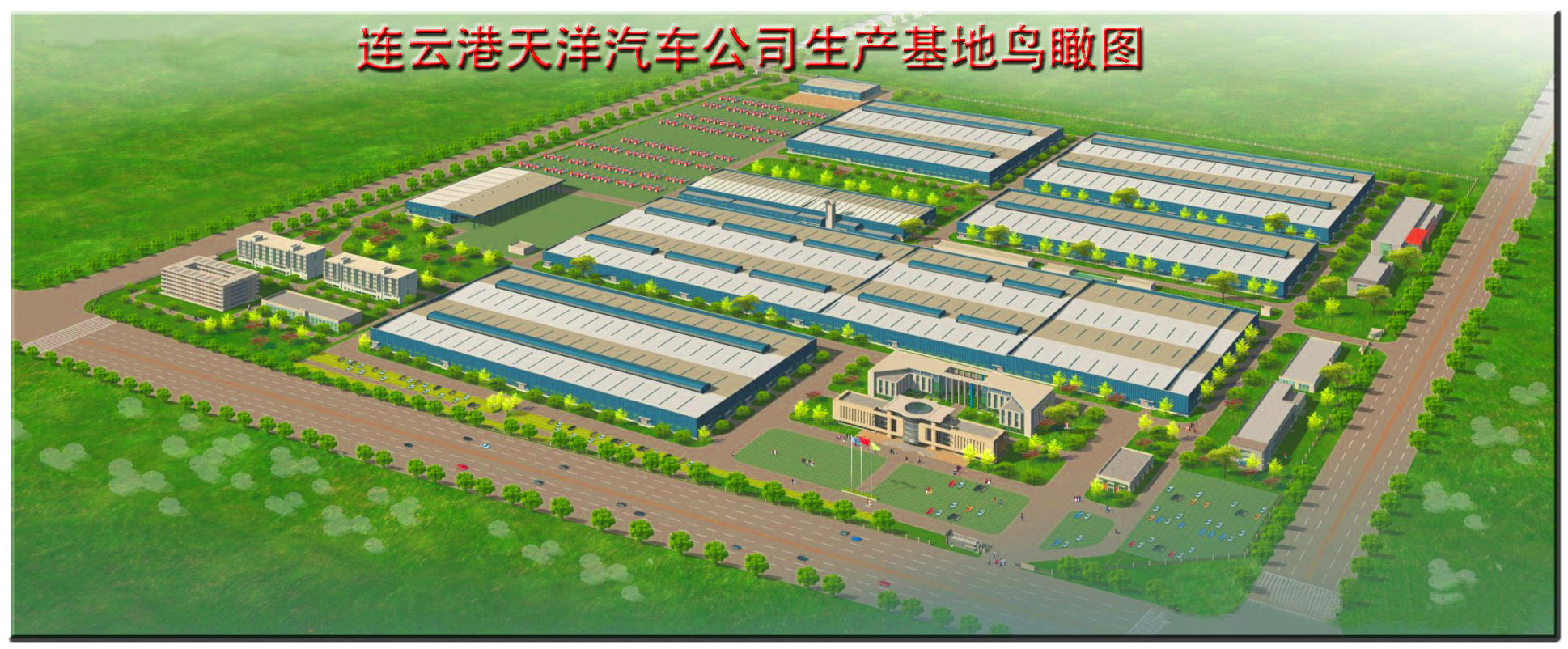

Lianyungang Tianyang Automobile Co., Ltd. is a private auto parts and vehicle manufacturing enterprise invested by Jiangsu Tianyang Group. The company was established on January 13, 2011. The company is located at No. 172 Dongfang Avenue, the national Lianyungang Economic and Technological Development Zone. It has a superior geographical location and convenient transportation. It is 40 kilometers away from Lianyungang Airport, adjacent to Ninglian Expressway, Lianhuo Expressway, Shenhai Expressway, 10 kilometers away from Lianyungang Port, and 10 kilometers away from Lianyungang East Railway Station. Station 6 kilometers. It is the starting point of the Lianhuo Expressway and the Eurasian Continental Bridge. The company is mainly engaged in R&D, production and sales of a series of heavy-duty trucks, SUVs, pickups and multi-purpose vehicles. The company plans to invest a total of 2.7 billion yuan and eventually form a production scale with an annual production capacity of 100,000 vehicles of various types.

The company has a registered capital of 160 million yuan and a total investment of 1.5 billion yuan in the first phase of the project. After reaching production in 2013, it will achieve sales revenue of 3 billion yuan and profits and taxes of 300 million yuan.

The construction land of the first phase of the project is 585,000 square meters (877 acres), with a construction area of 88,000 square meters. It has four major process workshops including stamping, welding, painting and final assembly, as well as a standard road test track for automobiles. It plans to have 1,500 employees, including more than 200 high-tech and management talents.

After the establishment of the company, it will have national quality control methods for complete vehicles and parts, and become a new complete vehicle and parts manufacturer integrating product research and development, production, sales and market services.

Tianyang factory and office building

The company has complete and advanced four process workshops of stamping, welding, painting and final assembly, a complete automobile road test track, national automobile mandatory inspection projects and parts quality control means.

Stamping Workshop

The stamping workshop covers an area of 12,000 square meters, has 600 sets of equipment, the largest press can reach 1,600 tons, and has a high-efficiency automatic flattening line for coil materials.

The stamping workshop can undertake the manufacturing tasks of a full set of stamping parts, and can carry out multi-variety mixed line production, with a production capacity of up to 60,000 vehicles per year in a single shift. There are currently 65 employees.